Hot water boilers ICI CALDAIE TNX, TNX EN, TNOX, REX, etc.

Hot water boilers ICI CALDAIE are gas–tube boilers made according to a three-way scheme or a two-way scheme with a reversible furnace. All boilers have a large water volume to ensure low heat load, lower flow rate to maintain boiler temperature and ensure a long service life. The boilers are designed for industrial applications and for large heating systems.

TNX is a heat generator with flue pipes with three flue gas revolutions with a washable bottom and automatic operation, designed for pressurized combustion of liquid or gaseous fuels for large heating systems with a capacity from 2500 to 6000 kW and an operating temperature from 60 to 100 °C. Designed for a maximum safety temperature of 110 °C (modifications are available for pressures up to 10 bar).

- Design pressure: 6 bar.

- Useful power: 3000-7000 kW.

- EFFICIENCY: 92.0%.

TNX EN is a heat generator with flue pipes with three flue gas revolutions with a washable bottom and automatic operation, designed for pressurized combustion of liquid or gaseous fuels for heating systems with a capacity from 8000 to 20,000 kW and an operating temperature from 60 to 100 °C. Designed for a maximum safety temperature of 110 °C (modifications are available for pressures up to 10 bar).

- Design pressure: 6 bar.

- Useful power: 8000 - 20,000 kW.

- EFFICIENCY: 92.0%.

TNOX. A boiler with flue pipes with three flue gas revolutions with a washed bottom with a low thermal load in the combustion chamber (thermal load from 1 to 1.2 MW/m3). With automatic operation, it is designed for pressurized combustion of liquid or gaseous fuels for large heating systems with a capacity from 2500 to 6000 kW and an operating temperature from 60 to 100 °C. Designed for a maximum safety temperature of 110 °C (modifications are available for design pressures up to 10 bar).

- Design pressure: 6 bar.

- Useful power: 2500 - 6000 kW.

- EFFICIENCY: 93.0%.

TNOX EN. A boiler with flue pipes with three flue gas revolutions with a washed bottom with a low thermal load in the combustion chamber (thermal load from 1 to 1.2 MW/m3). With automatic operation, it is designed for pressurized combustion of liquid or gaseous fuels for large heating systems with a capacity from 7000 to 17000 kW and an operating temperature from 60 to 100 °C. Designed for a maximum safety temperature of 110 °C (modifications are available for pressures up to 10 bar).

- Design pressure: 6 bar.

- Useful power: 7000 - 17000 kW.

- EFFICIENCY: 93.0%.

TNOX.e. Heat generator with flue pipes with three flue gas revolutions with a washable bottom and automatic operation, designed for pressurized combustion of liquid or gaseous fuels for large heating systems with a capacity from 2500 to 6000 kW and an operating temperature from 60 to 100 °C. It also has elements to accelerate heat transfer to ensure maximum possible performance in this category. Designed for a maximum safety temperature of 110 °C (modifications are available for pressures up to 10 bar).

- Design pressure: 6 bar.

- Useful power: 2500 - 6000 kW.

- EFFICIENCY: 95.2%.

TNOX BT COND. A steel boiler with three flue gas revolutions, with a washable bottom, with a built-in condenser connected in series with a generator, is designed for pressurized combustion of gaseous fuels for large heating systems with a capacity from 3,500 to 7,000 kW and an operating temperature from 40 to 100 °C. Designed for a maximum safety temperature of 110 °C.

- Design pressure: 6 bar.

- Useful power: 3000-7000 kW.

- EFFICIENCY: 107.5%.

TNOX.e EN. A boiler with chimneys with three flue gas revolutions, with a washed bottom, with a low thermal load in the combustion chamber (thermal load from 1 to 1.2 MW/m3). With automatic operation, it is designed for pressurized combustion of liquid or gaseous fuels for large heating systems with a capacity from 7000 to 17000 kW and an operating temperature from 60 to 100 °C. Designed for a maximum safety temperature of 110 °C (modifications are available for pressures up to 10 bar).

- Design pressure: 6 bar.

- Useful power: 7000 - 17000 kW.

- EFFICIENCY: 95.2%.

REX. A steel hot water boiler with a reversible flame furnace, cylindrical in shape, completely closed at the back by a convex bottom supported by a fully washable support. Compatible with air-charged burners for operation on liquid or gaseous fuels. It is intended for use in systems with a water temperature from 60 to 100 °C (the safety thermostat is set to 110 °C).

- Design pressure: 6 bar.

- Useful power: 4000 ÷ 6000 kW.

- EFFICIENCY: 92.5%.

REX-F. A steel hot water boiler with a reversible flame furnace, cylindrical in shape, completely closed at the back by a convex bottom supported by a fully washable support. Compatible with supercharged burners for gaseous fuel operation. It is intended for use in systems with a water temperature from 60 to 100 °C (the safety thermostat is set to 110 °C).

- Design pressure: 6 bar.

- Useful power: 4000 ÷ 6000 kW.

- EFFICIENCY: 95.3%.

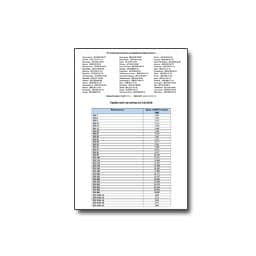

Model: 3000 TNX, TNX 3500, 4000 TNX, TNX 5000, 6000 TNX, TNX 7000, 8000 EN TNX, TNX EN 9000, 10000 EN TNX, TNX EN 11000, 12000 EN TNX, TNX EN 13000, 14000 EN TNX, TNX EN 15000, 16000 EN TNX, TNX EN 17000, 18000 EN TNX, TNX EN 19000, 20000 TNX EN, TNOX.e 2500, TNOX.e 3000, TNOX.e 3500, TNOX.e 4000, TNOX.e 5000, TNOX.e 6000, TNOX.e EN 7000, TNOX.e'en 8000, TNOX.e EN 9000, TNOX.e'en 10000, TNOX.e'en 11000, TNOX.e EN 12000, TNOX.e EN 13000, TNOX.e EN 14000, TNOX.e EN 15000, TNOX.e'en 16000, TNOX.e EN 17000, TNOX 1200 S, TNOX 1750 S, TNOX 2350 S, TNOX 2500, 2900 S TNOX, TNOX 3000, TNOX 3000 BT COND, TNOX 3500, 3500 TNOX BT COND, TNOX 3500 S, TNOX 4000, 4100 TNOX BT COND, TNOX 4100 S, TNOX 4800 BT COND, TNOX 4850 S, TNOX 5000, TNOX 5850 S, TNOX 6000, 6000 TNOX BT COND, TNOX 6850 S, TNOX 7000 BT COND, TNOX 7350 S, TNOX 8350 S, TNOX 9300 S TNOX 10500 S, TNOX 11600 S, TNOX 12500 S, TNOX 14000 S, TNOX EN 7000, TNOX EN 8000, TNOX EN 9000, TNOX EN 10000, TNOX EN 11000, 12000 TNOX EN, TNOX EN 13000, 14000 TNOX EN, TNOX EN 15000, 16000 TNOX EN, EN TNOX 17000, REX 400, 450, REX, REX 500, 600 REX, REX 400 F 450 F REX, REX 500 F to 600 F. REX

- Теплогенератор с дымовыми трубами TNX. Техническое описание.

- Генераторы тепла с дымовыми трубами TNX, TNOX. Руководство по эксплуатации.

- Генератор тепла с дымовыми трубами TNX EN. Техническое описание.

- Котлы с дымовыми трубами TNX EN, TNOX EN. Руководство по эксплуатации

- Котел с дымовыми трубами TNOX. Техническое описание.

- Котел с дымовыми трубами TNOX EN. Техническое описание.

- Теплогенератор с дымовыми трубами TNOX.e. Техническое описание.

- Котел из стали с тремя оборотами дымовых газов TNOX BT COND. Техническое описание.

- Котел с дымовыми трубами TNOX.e EN. Техническое описание.

- Водогрейный котел из стали REX. Техническое описание.

- Водогрейный котел из стали REX. Руководство по эксплуатации.

- Водогрейный котел из стали REX-F. Техническое описание.

- Котлы для теплиц TNOX S. Техническое описание.

All ICI CALDAIE products

About ICI CALDAIE

-

experience

The experience gained since 1958 has allowed the company to transfer the innovations achieved during the design and production of industrial steam boilers (a sector in which the company occupies a leading position) to commercial series boilers. -

reliability

The production of blanks is carried out using laser cutting and CNC machines; perfect welding of elements is provided by modern robotic complexes, each boiler is subjected to serious control, which indicates its reliability. -

volume

The plant annually supplies 12,000 commercial series hot water boilers and more than 1,000 industrial boilers, making this site the largest production site in Europe for the simultaneous production of both commercial and industrial series boilers.

NEW TECHNOLOGIES GROUP

Contact us or your local dealer for more information on certifications, features, reviews, pricing, stock availability and delivery terms for ICI CALDAIE products.

Reply guaranteed within 8 business hours

- (727)345-47-04

- (3955)60-70-56

- (8182)63-90-72

- (8512)99-46-04

- (3852)73-04-60

- (4722)40-23-64

- (4162)22-76-07

- (4832)59-03-52

- (8352)28-53-07

- (351)202-03-61

- (8202)49-02-64

- (3022)38-34-83

- (395)279-98-46

- (4932)77-34-06

- (3412)26-03-58

- (4012)72-03-81

- (4842)92-23-67

- (843)206-01-48

- (3842)65-04-62

- (4212)92-98-04

- (8332)68-02-04

- (4966)23-41-49

- (4942)77-07-48

- (861)203-40-90

- (391)204-63-61

- (3522)50-90-47

- (4712)77-13-04

- (4742)52-20-81

- (3519)55-03-13

- (375)257-127-884

- (495)268-04-70

- (8152)59-64-93

- (8552)20-53-41

- (831)429-08-12

- (3843)20-46-81

- (383)227-86-73

- (3496)41-32-12

- (3812)21-46-40

- (4862)44-53-42

- (3532)37-68-04

- (8412)22-31-16

- (342)205-81-47

- (8142)55-98-37

- (8112)59-10-37

- (863)308-18-15

- (4912)46-61-64

- (812)309-46-40

- (846)206-03-16

- (8342)22-96-24

- (845)249-38-78

- (8692)22-31-93

- (3652)67-13-56

- (4812)29-41-54

- (862)225-72-31

- (8652)20-65-13

- (3462)77-98-35

- (8212)25-95-17

- (4752)50-40-97

- (998)71-205-18-59

- (8482)63-91-07

- (3822)98-41-53

- (4872)33-79-87

- (4822)63-31-35

- (3452)66-21-18

- (347)229-48-12

- (3012)59-97-51

- (8422)24-23-59

- (8672)28-90-48

- (4922)49-43-18

- (423)249-28-31

- (844)278-03-48

- (8172)26-41-59

- (473)204-51-73

- (4112)23-90-97

- (4852)69-52-93

- (343)384-55-89