Steam boilers ICI CALDAIE FLASH, FX, BX, SIXEN, GSX, etc.

FLASH is an instant steam generator. Due to its characteristics, the FLASH generator is an ideal device for steam production for laundries and ironing rooms, as it is able to meet small and medium-sized dry steam needs while preventing overloads of thermal systems. The generator is ready for quick and easy installation: you only need to connect it to electrical, hydraulic networks and steam and drainage lines.

- Design pressure: 4.5 bar.

FX, FX DUAL is a steam generator with flue pipes, with reversible flare development, fully automatic, with high performance. The low water content and small size are the characteristics that make the FX generator the most suitable steam generation device for small and medium-sized facilities that require high-breakdown steam and reduced utilization to control the boiler room.

FX is a single version, FX DUAL is a modular version with two generators mounted on top of each other.

- Design pressure: 5 bar.

- Steam production: 50 ÷ 300 kg/h

- EFFICIENCY: 91%.

BX. Gas-tube monoblock steam generator with reversible flare development and a washable bottom of the furnace, complies with the Directive PED 97/23/EC (pressure equipment). It runs on liquid and gaseous fuels, and is supplied complete with regulating and safety equipment for automatic operation. The low-pressure flame inversion steam generator BX is characterized by the quality of the steam produced with saturation values approaching unity, even at high output peaks.

- Design pressure: 0.98 bar or 0.5 bar (called BBX) or 0.7 bar (for Russia, Belarus, Kazakhstan, Georgia, Ukraine).

- Steam production: 100 ÷ 3000 kg/h.

- EFFICIENCY: 91%.

SIXEN. Gas-tube monoblock steam generator with reversible flare development and a washable bottom, complies with the PED 97/23/EC Directive (pressure equipment). It runs on liquid and gaseous fuels, and is supplied complete with regulating and safety equipment for automatic operation.

- Design pressure: 12 bar or 15 bar.

- Steam production: 350 ÷ 5000 kg/h.

- EFFICIENCY: 90%.

GSX steam generator with three actual flue gas revolutions, monoblock, with excellent performance and original technical solutions, designed to ensure maximum reliability, durability and ease of operation. A semi-stationary horizontal type generator with 3 flue gas revolutions, a passing flame and a washed bottom.

- Design pressure: 12 bar or 15 bar.

- Steam production: 350 ÷ 5000 kg/h.

- EFFICIENCY: 91%.

GX. Gas-tube monoblock steam generator with three flue gas revolutions and a washable bottom, complies with the Directive PED 97/23/EC (pressure equipment). It runs on liquid and gaseous fuels, and is supplied complete with regulating and safety equipment for automatic operation.

- Design pressure: 12 bar or 15 bar.

- Steam production: 1700-25000 kg/h.

- EFFICIENCY: 90%.

The ICI GX S series steam generator with three flue gas revolutions, a passing flame and a washed bottom is equipped with a superheater, monoblock type, with automatic operation, with all fittings necessary for commissioning.

STX is a sliding frame equipped with components. An installation consisting of a water treatment system, a deaerator, a reservoir for collecting purges (recoverable) and forming a full-fledged steam station together with the boiler. Connected to a system for optimal energy saving management.

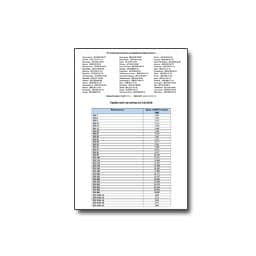

Model: FLASH, 16, 24, FLASH, FLASH, 60, 60 COMBI-FLASH, FLASH, 80, FLASH, 180, 50 FX, 50 FX, FX 100, FX 100 DUAL, 150 FX, FX 200 DUAL, DUAL FX-300, FX 600, 60 BX, 60 BX exp BX 90, 90 exp BX, BX 200, 200 exp BX, BX 300, 300 exp BX, BX 400, 400 exp BX, BX 500, 500 exp BX, BX 600, 600 BX exp BX 800, exp 800 BX, BX 1000, 1000 exp BX, BX 1200, 1200 exp BX, BX 1500, 1500 exp BX, BX 1750, 1750 exp BX, SIXEN 350, 350 exp SIXEN, SIXEN 500, SIXEN 500 exp, SIXEN 650, SIXEN 650 exp, SIXEN 800, exp 800 SIXEN, SIXEN 1000, 1000 exp SIXEN, SIXEN 1350, 1350 exp SIXEN, SIXEN 1700, 1700 exp SIXEN, SIXEN 2000, SIXEN 2000 exp, SIXEN 2500, 2600 SIXEN exp SIXEN 3000, 3000 exp SIXEN, SIXEN 3500, 3500 exp SIXEN, SIXEN 4000, SIXEN 4000 exp, SIXEN 5000, 5000 exp SIXEN, SIXEN 350 N, N SIXEN 500, SIXEN N 650 N 800 SIXEN, SIXEN N 1000, N-1300 SIXEN, SIXEN 1700 N, N SIXEN 2000, SIXEN N 2500, 3000 SIXEN N, N SIXEN 3500, 4000 SIXEN N, N SIXEN 5000, SIXEN stx 350, SIXEN stx 500, SIXEN stx 650, 800 SIXEN stx, stx SIXEN 1000, SIXEN stx 1300, 1700 SIXEN stx, stx SIXEN 2000, SIXEN stx 2500, 3000 SIXEN stx, stx SIXEN 3500, 4000 SIXEN stx, stx SIXEN 5000, TReVAPOR 1200, 1500 TReVAPOR, TReVAPOR 2000, TReVAPOR 2500, 3000 TReVAPOR, TReVAPOR 3500, 4000 TReVAPOR, TReVAPOR 5000, 6000 TReVAPOR, TReVAPOR P 1200, TReVAPOR P 1500, TReVAPOR P 2000, P TReVAPOR 2500, 3000 TReVAPOR P, P TReVAPOR 3500, 4000 TReVAPOR P, P TReVAPOR 5000, 6000 TReVAPOR P, GSX, GX 1000, 1200 GX, GX 1500, 1750 GX, GX-2000, GX 2500, GX 3000, 3500 GX, GX 4000, 5000 GX, GX 6000, 7000 GX, GX 8000, 9000 GX, GX 10000, 12000 GX, GX 13000, 15000 GX, GX'S, STX 2-5, 6-8 STX, STX 10-20, 15-20 STX, STX 25-30, AX 200 12, 15 AX 200, 300 12 AX, AX 300 15, 12 AX 400, 400 15 AX, AX 500 12, 500 15 AX, AX 600 12, 15 600 AX, AX 800 12, 15 800 AX, AX 1000 12, 15 AX, 1000, 1200 AX 12, 15 1200 AX, AX 1500 12, 15 AX 1500, 1750 12 AX, AX 1750 15, 2000 12 AX, AX 2000 15, AX 2500 12, 15 AX 2500, 3000 12 AX, AX 3000 15, BNX 100, 150 BNX, BNX 350, BNX 500, BNX 700, BNX 850, 1000 BNX, BNX 1400, BNX 1700, BNX 2000, BNX 2650, 3000 BNX, PX 100, PX 150 PX 200 PX 300, 200 EVX, EVX 300, 400 EVX, EVX 500, 600 EVX, EVX 800, 1000 EVX, EVX 1200, 1500 EVX, EVX 2000, 2500 EVX, EVX 3000, 4000 EVX, EVX 5000, 6000 EVX, EVX 8000, 9000 EVX, 4 ISG, ISG 5, 7 ISG, ISG 8, 10 ISG, ISG 12.

- Мгновенный парогенератор FLASH. Техническое описание.

- Парогенераторы с дымогарными трубами FX, FX DUAL. Техническое описание.

- Парогенераторы с дымогарными трубами FX, FX DUAL. Руководство по эксплуатации.

- Газотрубный моноблочный парогенератор BX. Техническое описание.

- Газотрубный моноблочный парогенератор BX. Руководство по эксплуатации.

- Газотрубный моноблочный парогенератор SIXEN. Техническое описание.

- Газотрубный моноблочный парогенератор SIXEN. Руководство по эксплуатации.

- Газотрубный моноблочный парогенератор SIXEN 5000 N EXP. Техническое описание.

- Генератор пара GSX. Техническое описание.

- Газотрубный моноблочный парогенератор GX. Техническое описание.

- Генератор пара GSX. Руководство по эксплуатации.

- Парогенератор GX S. Техническое описание.

- Салазочная рама STX. Техническое описание.

- Котлы паровые и генераторы пара AX, BNX, PX, SIXEN N, SIXEN stx, TReVAPOR, EVX, ISG. Техническое описание.

All ICI CALDAIE products

About ICI CALDAIE

-

experience

The experience gained since 1958 has allowed the company to transfer the innovations achieved during the design and production of industrial steam boilers (a sector in which the company occupies a leading position) to commercial series boilers. -

reliability

The production of blanks is carried out using laser cutting and CNC machines; perfect welding of elements is provided by modern robotic complexes, each boiler is subjected to serious control, which indicates its reliability. -

volume

The plant annually supplies 12,000 commercial series hot water boilers and more than 1,000 industrial boilers, making this site the largest production site in Europe for the simultaneous production of both commercial and industrial series boilers.

NEW TECHNOLOGIES GROUP

Contact us or your local dealer for more information on certifications, features, reviews, pricing, stock availability and delivery terms for ICI CALDAIE products.

Reply guaranteed within 8 business hours

- (727)345-47-04

- (3955)60-70-56

- (8182)63-90-72

- (8512)99-46-04

- (3852)73-04-60

- (4722)40-23-64

- (4162)22-76-07

- (4832)59-03-52

- (8352)28-53-07

- (351)202-03-61

- (8202)49-02-64

- (3022)38-34-83

- (395)279-98-46

- (4932)77-34-06

- (3412)26-03-58

- (4012)72-03-81

- (4842)92-23-67

- (843)206-01-48

- (3842)65-04-62

- (4212)92-98-04

- (8332)68-02-04

- (4966)23-41-49

- (4942)77-07-48

- (861)203-40-90

- (391)204-63-61

- (3522)50-90-47

- (4712)77-13-04

- (4742)52-20-81

- (3519)55-03-13

- (375)257-127-884

- (495)268-04-70

- (8152)59-64-93

- (8552)20-53-41

- (831)429-08-12

- (3843)20-46-81

- (383)227-86-73

- (3496)41-32-12

- (3812)21-46-40

- (4862)44-53-42

- (3532)37-68-04

- (8412)22-31-16

- (342)205-81-47

- (8142)55-98-37

- (8112)59-10-37

- (863)308-18-15

- (4912)46-61-64

- (812)309-46-40

- (846)206-03-16

- (8342)22-96-24

- (845)249-38-78

- (8692)22-31-93

- (3652)67-13-56

- (4812)29-41-54

- (862)225-72-31

- (8652)20-65-13

- (3462)77-98-35

- (8212)25-95-17

- (4752)50-40-97

- (998)71-205-18-59

- (8482)63-91-07

- (3822)98-41-53

- (4872)33-79-87

- (4822)63-31-35

- (3452)66-21-18

- (347)229-48-12

- (3012)59-97-51

- (8422)24-23-59

- (8672)28-90-48

- (4922)49-43-18

- (423)249-28-31

- (844)278-03-48

- (8172)26-41-59

- (473)204-51-73

- (4112)23-90-97

- (4852)69-52-93

- (343)384-55-89